TINY OFF-GRID HOUSE WATER DISTRIBUTION SYSTEM

Image Courtesy of Home Depot

Uponor, formerly known as Wirsbo’s, non-toxic (Lead free) PEX Tubing and ProPEX fittings and rings will be used for transport of pretreatment and filtered water in the Tiny Off Grid House.

Crosslinked Polyethylene (PEX): P = Poly E = Ethylene X = Cross Linked (Hydrogen/Carbon bonds are crossed linked for strength and flexibility)

PEX Was first manufactured in the mid 1960’s in Europe, then in the mid 1980’s it was introduced to te United States where it was used in radiant floor heating systems and eventually by the mid 1990’s for residential plumbing.

PEX Tubing is manufactured in various colors; which facilitates plumbing organization. For the Tiny Off Grid House, blue PEX tubing will be used to transport cold and unfiltered water while red PEX tubing will transport hot water.

For this project, PEX-A was chosen over PEX-B and definately Copper pipes. Since the PEX-A is not intended for radiant floor heating or a boiler, a PEX tubing with an oxygen barrier is not needed. Lets start with the Cons, then elaborate after on what are the benefits of PEX-A?

PEX-A CONS:

More expensive than PEX-B; yet, far cheaper than Copper pipes

PEX can release toxic gases in a fire

Ultraviolet (UV) rays degrade PEX. Exposure to the sun outside or through windows must be avoided because it reduces PEX resistance to chlorine.

PEX can not be used for water temperatures that exceed 180*F at 100 PSI.

In colder temperatures, PEX-A is less resilient to bursting compared to PEX-B.

Susceptible to rodent bites

Not currently recyclable

PEX-A PROS:

PEX has no known theft concerns since it is not a precious metal like Copper

PEX-A is stronger and more flexible than PEX-B. PEX A is manufactured by a method called extrusion and coiled on spools. This allows for easier installation since the long PEX-A has no coil memory it can be easily threaded straight through walls or around 90 degree corners seamlessly; requiring no splicing, fewer connections or elbow fittings than Copper pipe would

PEX-A is more forgiving than PEX-B and obviously Copper; a heat-gun can easily repair a kink sustained in PEX-A tubing. PEX-B does not have this capability to undue kinks

To undue an expansion fitting, apply heat then cut the fitting; careful not to cut the fitting.

According to Uponor, their PEX-A “expands up to 3X its diameter to help resist freeze damage.” Water can freeze in either PEX-A or Copper tubing. However, since Copper can not expand like PEX-A frozen water can burst rigid Copper pipes. PEX-A is made of plastic which can expand along with the frozen water —to a generous point—then as the water melts, PEX contracts to resume its original diameter. This flexibility also helps PEX absorb water pressure preventing water hammer noises.

During transport of the Tiny Off-Grid House the flexible PEX tubing should not be impacted by movement or vibrations; unlike rigid metallic piping and CPVC (Chlorinated Poly Vinyl Cloride).

CRIMP FITTINGS VS COMPRESSION FITTINGS :

PEX B uses crimp fittings (ASTM F1807 Metal inserts fittings or F2159 Plastic insert fittings). A nonproprietary manual crimp tool squeezes a stainless steel clamp ring over the end of the PEX tube and inserted fitting. The installation is checked with a No / No-Go gauge for a correct leak free fitting. The main disadvantage of the crimp fitting is the low water flow created down stream due to the smaller inner diameter of the fitting inserted in the PEX tubing. Also, in tight spaces, during installation the bulky crimp tool may not be able to fit in tight spaces.

Image Courtesy of Home Depot

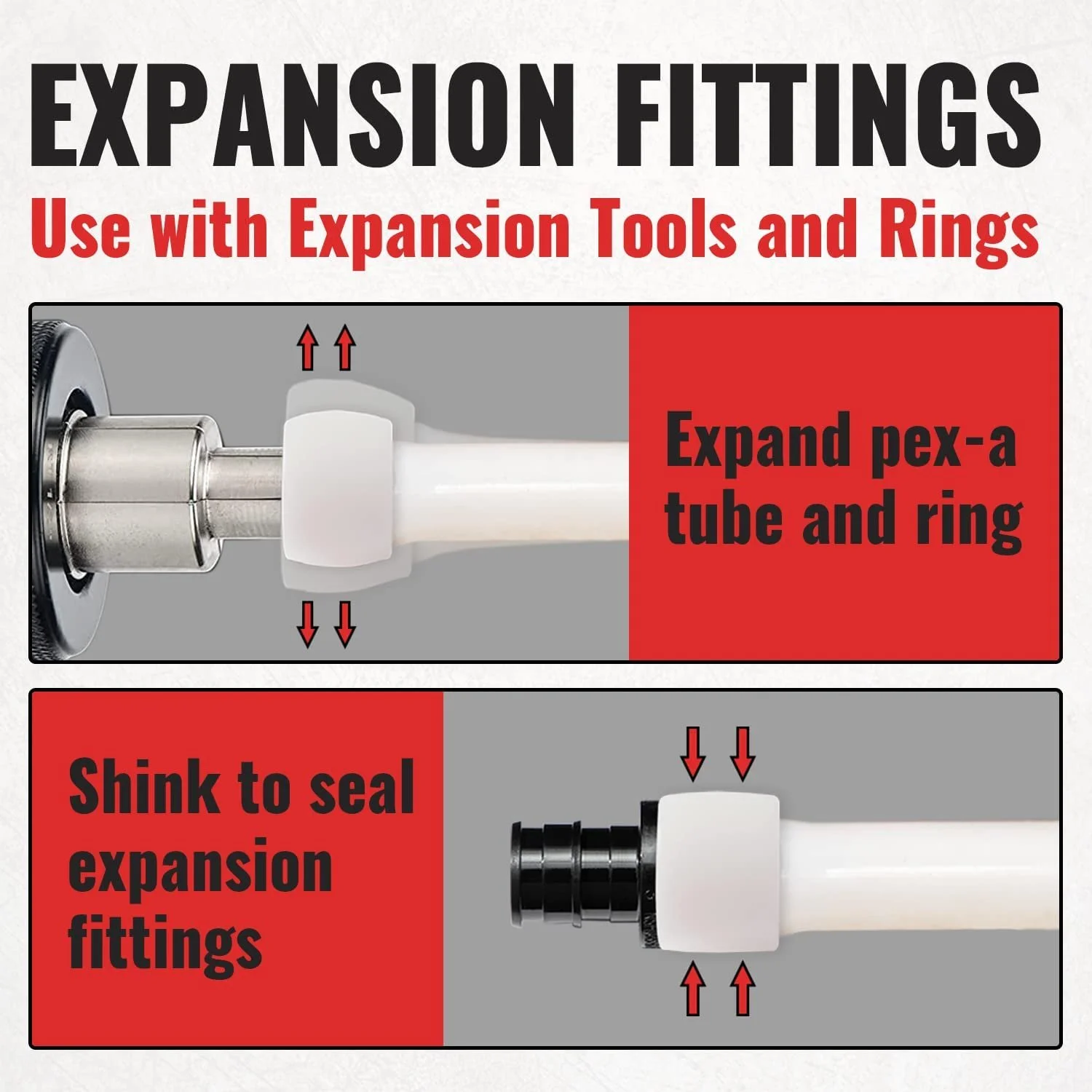

ProPEX A cold Expansion fittings with stop edge (ASTM F1960) are used to make permanent connections which are fast and easy to install compared to copper soldered connections; reducing labor cost. A Milwaukee ProPEX M12 expansion tool, with an auto-rotation expansion tip, is used to expand the PEX tubing (1/2”, 3/4” to 1”) to a fluted end enabling it to receive the Uponor fitting ($3.34 USD Each). The Milwaukee ProPEX M18 model has auto-rotation expansion fittings size 1/2” , 3/4”, 1”, 1 1/4” to 1 1/2”. The ProPEX expansion fittings actually become tighter over time; with 1,000 pounds of radial force. Yet, the ProPEX expansion fittings still allow for the rotation of the connectors after compression for positioning during installation of plumbing system. Subsequently, the fittings does not require the use of adhesives, glues, torches or flux. In tight spaces, the PEX fitting can be expanded and the connection made by simply sliding the PEX inside without having to force a bulky tool in the tight space.

Image Courtesy of Ubuy

The ProPEX expansion ring, which is larger than the inner diameter of the PEX tubing, does not reduce the inner diameter size of the fitting. This allows the water flow/pressure to remain the same throughout the entire length of the PEX water distribution system. While PEX-B reduced size clamp fittings have the potential to reduce water pressure down stream in the distribution system.

Some rules do need to be respected when making connections with two ProPEX fittings that are close together:

Each expansion ring has to be fully expanded at the same time before inserting the two fittings

Follow manufacturer recommended minimum pipe length in relation to connector size

Copper and Brass will not be used in piping, connections, or Tee’s to avoid metal exposure and maintain the contraction/expansion continuity of the PEX A tubing; along with avoiding the potential for dezincification of Brass connections.

PEX A is safer than Copper since soldering is eliminated:

No exposure to flames from a torch.

No exposure to lead based solder and acid fluxes.

PEX A is unaffected by chlorinated, acidic (pH < 6.5) and soft water that are known to corrode the inside of Copper pipes or cause pin hole leaks through the copper pipes.

PEX A expands and contracts more than copper so liberal installation of tubing length is necessary with slack to allow for expansion/contraction movements.

A continuous coil of PEX A will be used for the general plumbing. While for short runs, it’s maybe better to use a manufactured straight PEX A.

The inner lining of PEX A tubing is smooth which does not facilitate mineral deposits or bacteria attaching to the inner lining that would create colonies of biofilm.

Image Courtesy of Viega

The Viega ManaBloc distribution Lead Free Manifold will be installed in the bathroom; recessed in a water well in the wall behind the mirror. Within the structural wall frame, the PEX A tubes will be encapsulated in closed cell insulation then shielded behind ZIP insulated panels where it will be insulated from cold weather temperatures and shielded from UV rays. This negates the need for manufactured insulated PEX tubing.

Compared to traditional trunk and branch plumbing systems, the Manifold does not require reducing the pipe diameter as it gets closer to each water outlet in order to keep maintain the water pressure.

The PEX A tubing can be seamless throughout the distribution run between the Manifold and water outlets avoiding the need for vulnerable joints along the way.

Since each water outlet has its own dedicated PEX A tubing run there will be less pressure and temperature fluctuations. The dedicated PEX A tube runs will allow for a consistent smaller diameter tubing along the PEX tubing run—using less water and energy.

The durable Vega ManaBloc Manifold is made of polysulfonate plastic. According to Viega “This material is used extensively in the medical industry and is highly resistant to hot water, chlorine and other chemical typically found in potable water systems.”

Most common plastic pipes used in drinking water plumbing exhibit some form of chemical leaching. Preliminary findings show some brands of PEX may exhibit chemical leaching that may not be exhibited in other PEX brands. One chemical that has the potential to be leached from PEX is Ether “ethyl-tert-butyl ether” (ETBE) which is a PEX pipe manufacturing byproduct. PEX has been used extensively in U.S. drinking water plumbing with no known immediate impact to water quality. The Tiny Off-Grid House Research will seek to confirm the impact of chemical leaching; if any, along with other pro’s and con’s of the material use. A more immediate threat to water quality are metals, like Aluminum, “intentionally” added to U.S. municipal drinking water as a flocculant to enhance its aesthetics.

Although PEX is recognized in all U.S. building codes and is approved for domestic plumbing in all 50 states, please check your local/city plumbing codes since there is not one unified national plumbing code system.

Please share your thoughts or experiences in the Comments section below.