OFF-GRID LITHIUM IRON PHOSPHATE BATTERY

Photo courtesy of Dragonfly Energy

The two most popular types of batteries for off-grid energy storage are deep cycle “Sealed" Lead (Pb) Acid (SLA) batteries and Lithium Iron phosphate (LiFePo4) batteries also called Li-Ion batteries.

Of the SLA batteries the three most common types are flooded, absorbed glass mat (AGM) and Gel types. The AGM has glass matts sandwiched between plates suspended in electrolyte solution. The glass matts are susceptible to damage between the plates due to vibrations. A improvement of the glass matts are Gels types which have an electrolyte solution suspended inside a silica gel. Unlike flooded lead acid batteries, AGM and Gels batteries do not require ventilation due to off gassing or the maintenance of refilling the electrolyte solution in the battery. Since spillage and corrosion are not a concern, the AGM and Gels sealed batteries can be mounted horizontal in a confined compartment.

Car and golf cart batteries should not be used for solar power storage applications because they do not have the endurance needed to sustain a huge electrical load for an extended period of time. Car batteries are designed to discharge a short high current of energy to start a vehicle engine and is not required to sustain this high energy to keep the engine running. Car batteries are like a sprinter runner while an AGM and Gels batteries are more like long distance runners.

The amount of energy a battery can store is called “capacity.” The capacity of a battery is measured in amp hours (Ahs). A 200 Ah battery may deliver 20 amperes of current for 10 hours. (200Ah ÷ 20A = 10 hrs); under standard temperature conditions 77 °F / 25 °C.

“An ampere is the unit of measurement used for electrical current and is defined as a coulomb of charge passing through an electrical conductor in one second.” https://www.engineersedge.com/battery/capacity_battery_ratings.htm

The battery storage capacity is “measured” in kilowatt hour (kWh). The amount of energy a typical home in the U.S. consumes daily is measured in kilowatt hour (kWh). For reference, the average U.S. home uses 28 kWh per day.

A battery depth of discharge (DOD) is how much percentage of energy that can be used before each recharge. Lead —and flooded— Acid battery DOD is only 50% of its full storage capacity. A discharge more than 50% will decrease the total recharge “lifecycles.”

Each time a battery is discharged and recharged is known as a cycle or charge cycle. The more a battery is discharged the life expectancy will be proportional decreased. Even if a battery is halfway discharged, then recharged, it’s still considered a one cycle recharge. “Lithium” batteries discharge slowly to their lowest state of charge, then recharge fully again. But since Lithium batteries can be discharged up to 100% they have a greater life expectancy, compared to Lead Acid batteries, since they require less number of recharges. If you discharge your “Lead” battery more tan 50% you risk damage to the battery.

Lead Acid DOD = 50% daily @700 recharge cycles, 4 years longevity

Lithium Ion DOD = 80 - 100% daily @2500 recharge cycles, 7 years of longevity

Lead Acid charging efficiency is 85% - 90%. While Li batteries charging efficiency is 99%. In an off-grid solar system this efficiency is very important.

Lead Acid battery voltage drops as the capacity lowers. While Li batteries voltage remains constant until the battery is fully discharged.

Lead acid batteries, at the same storage capacity as Lithium ion are larger and heavier than Li batteries.

If both Lead Acid and Li batteries sustain traumatic damage, or are subjected to excessive heat, the batteries performance will be compromised or even permanently damaged.

Lithium Ion (Deep cycle) batteries come in different chemistries depending on their manufacturer with Lithium the constant ingredient. Lithium batteries are resource intensive not inherently because of the mineral that carries its name, but for the conflict mineral Cobalt (Co) that makes up to 30% of a Lithium battery chemistry. A standard electric vehicle power may contain approximately 14 Kg of Cobalt. Lithium in the form of Lithium Hydroxide (LiOH) actually only makes up a very small part of the four components in Lithium battery chemistry (Electrolyte, Cathode, Anode and a porous Separator). Yet, Lithium is found in every rechargeable battery. The Electrolyte is made of Lithium Salt in an organic solvent, while the Cathode (+) also contains Lithium and other minerals like Aluminum & Manganese . . . The Anode (-) is made of carbon Graphite. The porous Separator allows the chemistry flow of electrolyte solution from the Cathode to the Anode during discharge. While recharging, the chemistry flows from the Anode to the Cathode. The world’s largest producer of Cobalt, Democratic Republic of The Congo (DRC), accounts for 60% of global production; 100,000 MT's in 2019. Cobalt is easier & cheaper to extract in the DRC compared to Australia; the global #2 producer of Cobalt. Control of the Cobalt mines in the DRC are crucial to the funding of armed groups whom wage wars and dominate the population. The armed groups impose corruption, sexual exploitation, forced labor, child labor, unsafe working conditions and cause environmental pollution . . . Most of the DRC mines use modern mechanical equipment while atleast 20% rely on rudimentary hand tools (Artisanal mines). Electric Vehicle (EV) manufacturers are making advances in Lithium battery technology to reduce, or eliminate, the use of Cobalt in their Lithium batteries.

Although Lithium is an abundant mineral and part of its production uses natural sunlight and wind to evaporate large brine pools, its production is not benign from social conflicts or environmental impacts. At the time of this writing, the South American Lithium Triangle (Argentina, Bolivia & Chile) accounts for 80% of global Lithium Carbonate, Li2CO3 (19% Lithium content) production and contributes to the depletion of underground aquifers; especially in the Salara salt flats of Altacama. The indigenous Altacama community have been protesting Lithium mining companies disregard for water consumption quotas. The impact of lowering aquifer levels has caused Algarrobo trees, native species of resilient hardwoods able to survive living in the desert, to start dying. The Algarrobo trees evolved to survive in the harsh desert conditions for millennium by sending their roots down deep in to the once accessible underground aquifers to absorb water and minerals. Could the dying Algarrobo trees be a canary in a cage when it comes to the Altacama rapidly depleting aquifer levels?

Lithium is not new to industry. It has historically been used in industry as an alloy and for hydrodesulfurization in ICE vehicles to remove sulfur from liquid carbon fuels. With the increased use of EV’s even the cost of abundant Lithium along with the already strained Nickel will inevitably increase. Nickel is a large component of a Lithium battery. For now only 5% of Class 1 Nickel (Purity >99.8%) are used in rechargeable battery production. The remaining 95% is used in stainless steel production, metal plating and alloys. This will obviously change in the future as the two industries compete for Nickel.

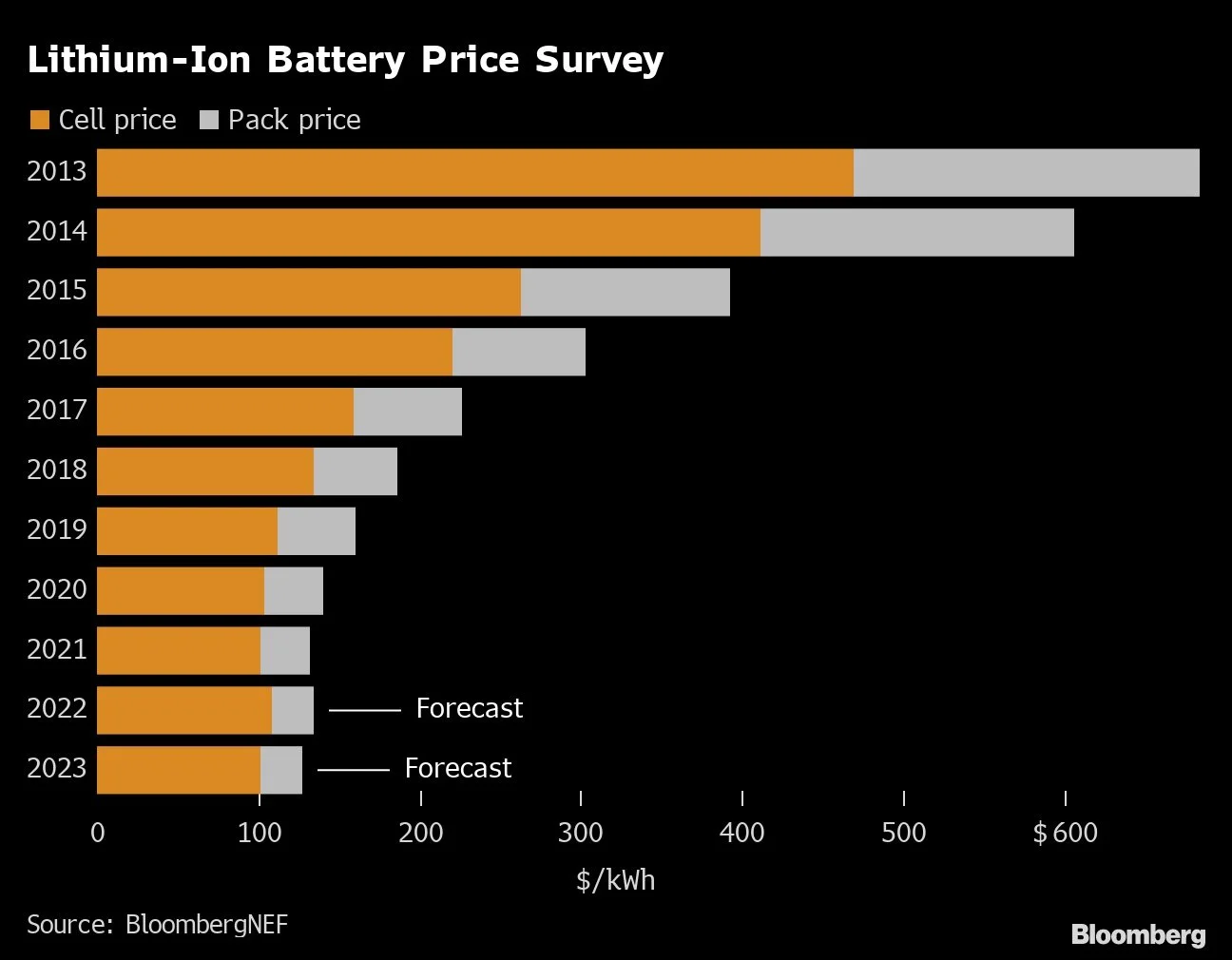

Technological improvements and efficient manufacturing have created a gradual decline in the cost of Lithium batteries. According to a report published by Bloomberg Lithium batteries prices have seen a 80% decline in prices from 2010 to 2017.

Photo courtesy of Bloomberg

Wiring Batteries in Series:

Series wiring the voltage increases while the current (Amps) remains the same

Photo courtesy of Nomadic Moments

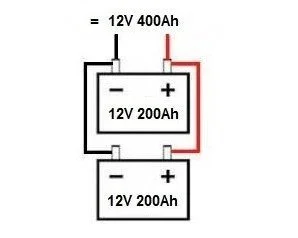

Wiring Batteries in Parallel:

Photo courtesy of Nomadic Moments

Parallel wiring the current (Amp) increases while the voltage remains the same

NOTE: When wiring batteries, the linear distance of the DC output polarity, positive & negative, conductors between the battery bank and Victron Lynx Distributor should be identical lengths; with the shunt and on/off switch included. Also, the output polarity, positive & negative, conductors should leave from opposite directions of the battery bank; not out the same battery. This configuration ensures all the internal resistance are equal in the battery bank which means they all charge and discharge equally. If they both exit the battery bank from the same side the first battery in the series it will have more resistance because it has to send more current through more length of wiring. Also, the batteries do not get used equally. Instead, they are charged by the battery preceding them on the line; exhausting the preceding battery first.

Series / Parallel Wiring:

Photo courtesy of Nomadic Moments

The voltage and the current (Amps) both increase.

The series wiring should come first, then the parallel wiring.

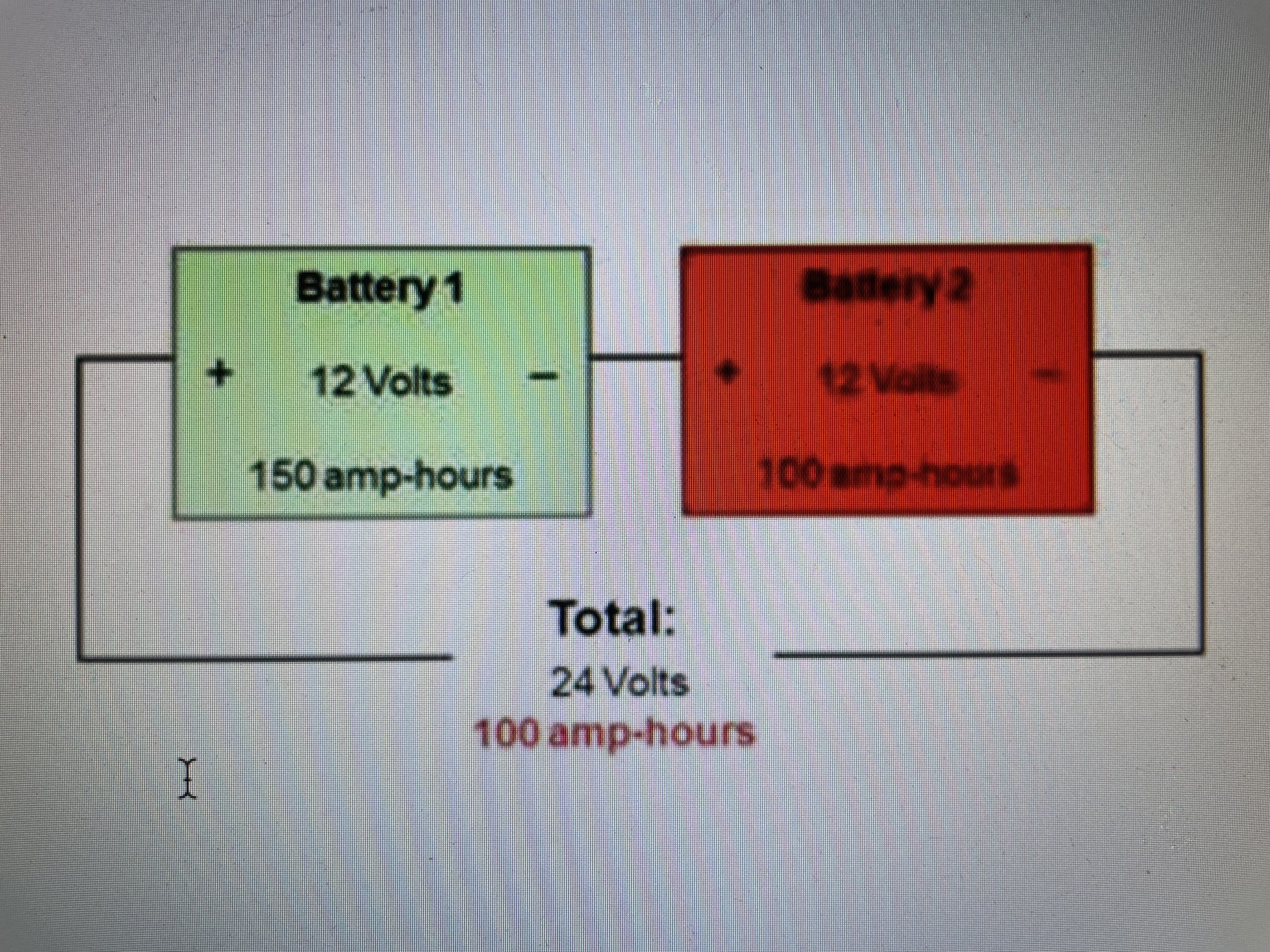

Wiring Batteries With Different Currents:

The battery bank should have all the same current (Amps) because the lowest current capacity battery will lower the overall current of the battery bank regardless of the higher current levels of the other batteries.

In any battery wiring configuration, connecting more than one wire lug on to a single battery terminal requires that both lugs be positioned on the same side of the terminal; with each lug in physical contact with each other, with no washer or nut in between their union. This method mitigates heat since the energy will flow through the wires and lugs and not the battery or its terminals.

The use of solid Copper bus bars for parallel wiring of the battery bank is not an option due to the potential for failure from vibrations during transport of the Tiny Off-Grid House.

The clean renewable energy generation will be consumed and stored in twenty-four, 24 Volt nominal, 50 Amp Battle Born LiFePO4 batteries, manufactured by Dragonfly Energy, wired in series/parallel providing a total of 48 volts, 600 amps of energy storage. The battery bank capacity is sufficient for the Tiny Off-Grid House energy needs and adaptable for integration of unforeseen technological advancements.

How To Calculate Kwh’s of 50 Amp, 24 Volts, wired in pairs of series/parallel:

24Vs x 2 = 48Volts, 50Amp Hours (Ah) x 12 pairs = 600 Ahs. 48Vs x 600 Ahs = 28,800 ÷ 1000 = 28.8 Kwh of battery storage.

Photo courtesy of Dragonfly Energy

The Battle Born LiFePO4 (LFP) battery system was selected because of its history of robust off-grid capabilities, energy efficiency and absence of Cobalt. The Cobalt is replaced with Iron which is a stable accessible, abundant element The battery system should be able to provide a full 28.8 kWh of continuous power to service the daily energy needs of the Tiny Off-Grid House. Compared to the Tesla Powerwall 2 which has a storage capacity of 13.5 kWh Kilowatt hours but is only capable of 5kW continuous discharge with 7kW at short 10 second bursts. The low 5 kW continuous power was probably designed by Tesla to prolong the life expectancy of the battery system which unfortunately put it at a disadvantage in an off-grid environment.

The Battle Born Lithium Deep Cycle Battery has a lifespan of 3000 - 5000 recharge cycles at 100% DOD at normal operating temperatures. According to Battle Born, in low temperatures, “the batteries will no longer accept a charge" once the temperature drops to 24 °F but they will continue to discharge until the temperature reaches -4 °F. The use of insulated battery boxes, or heating blankets are recommended to help keep the temperature up on the batteries. As far as heat is concerned, the Battle Born batteries will shut down once the temperature hits 135 °F”

The Battle Born battery LiFePO4 chemistry does not contain Copper. As conscious consumers, we should make critical decisions on the products we choose to purchase. Our consumer choices should not support a battery chemistry that inadvertently contributes to conflict in a region of the world affecting people already suffering from poverty and injustice. Our choices as conscious consumers should encourage battery manufacturers to continue to pursue other battery chemistry that increases battery storage density and eliminates the dependence on conflict resources like Cobalt.

The Battle Born batteries will be arranged in two rows on the floor of the engineering compartment; located in the bow of the trailer. This arrangement will help to ballast the trailer during towing.

The engineering compartment will be insulated with SPF even on the sides facing the living space. The engineering compartment heat source will be heat pads under the rows of batteries. Exhaust fans, installed high on the compartment wall, will remove stale air and allow the heat to dissipate outside.

Recycling

Lead acid batteries are 100% recyclable. It is more economical to recycle materials than to mine for virgin materials. Dragonfly Energy is currently researching ways to recycle their R/D and end of life Lithium batteries.

Recycling Methods:

Pyrometallurgy burns the batteries to extract low to medium amounts of Cobalt while producing toxic waste

Hydrometallurgy is a low energy method of using acids and solutions to extract Li, Ni, Mg, Co and Au from the batteries without toxic by-product

Ultrasonic low frequency sound is used to separate components

Biohydrometallurgical uses bacteria to separate the components. Although cost effective, it is a slow process

Second Life:

Lithium batteries capacity degrades very slowly which makes Lithium batteries ideal for second hand use because the batteries still holds further usable capacity for lower energy applications. Companies like BigBattery purchase used Lithium batteries, with atleast 80 to 85% capacity, to create power supply systems.

Next Generation:

The next generation of high energy density batteries are solid state batteries. Fluid and solid state batteries both use Lithium as their electrolyte to control the flow of ions between the positive cathodes and negative anodes to produce energy. However, as the name implies, solid state batteries have thin layers of solid electrolyte that serves as the cathode, anode and separator combined. Solid state batteries exceed Lithium fluid batteries in energy density, faster recharge times, maintaining 90% of its capacity after 5,000 cycles, are smaller in size and weight along with longer range. The latter is especially important in the electric vehicle (EV) industry which is investing heavily in solid state technology and its scalability of production to power the next gen EV’s.

Please share your thoughts or experiences in the Comments section below.