ELECTRIC VEHICLES, A PROBLEM OR A SOLUTION?

Photo courtesy of iStock

The International Energy Agency (IEA) predicts that by 2030 Electric vehicles (EV) will represent more than 60% of all vehicles sold globally. This growth is nurtured, in some countries, by government tax credits, state tax rebates, range anxieties eased by advancements in long range batteries, increased accessibility of Level 3 DC fast charging stations along highways, increased Level 2 street chargers, HOV lane privileges, increase consumer awareness of climate change, along with an increase in new varieties of EV models and finally some parity in prices with legacy internal combustion engine (ICE) vehicles. In countries like the United States and Norway, governmental CO₂ emissions reduction regulations and financial incentives for EV consumers reduced the cost of EV’s; through Inflation Reduction Act tax rebates or taxation based on vehicle emissions production; in the United States & Norway. respectively.

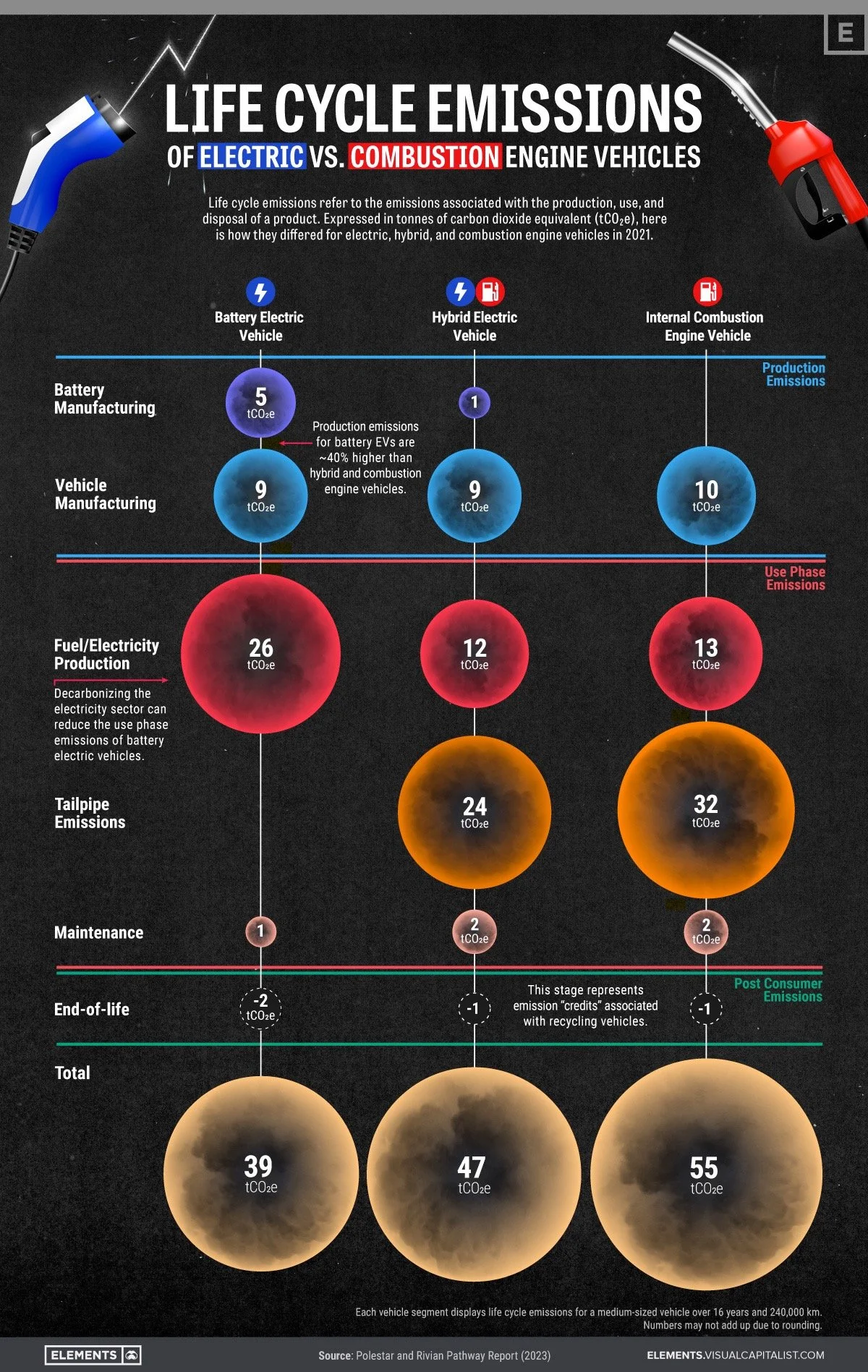

A study by the Massachusetts Institute of Technology Energy Initiative found that the manufacturing of EV’s generates 60% more CO₂ emissions than ICE vehicles. Most of these emissions come from the energy intensive manufacturing of lithium-ion batteries. The production phase of an average EV sedan, with a long-range lithium-ion battery bank, produces 8.8 metric tons of CO₂e (43% from the battery); in comparison, an ICE vehicle generates up to 5.6 metric tons of CO₂e during the production phase; but with an additional 50 metric tons of “lifetime” CO₂ tail-pipe emissions. The entire green house gas (GHG) “lifetime emissions” of ICE vehicles are still higher than the emissions generated during production of EV’s; plus, EV’s have no post production “driving” CO₂ emissions if the electricity is obtained from renewable energy sources. So a large part of the “embedded carbon” generated during EV production can be off-set by their lifetime mechanical efficiency and by sourcing carbon free electrical energy

Photo courtesy of Elements

Since the invention of the first Model T combustion engine a 100 years ago little technological progress has been made in combustion engines miles per gallon (MPG) efficiency, which remains at a dismal 30% of efficiency. On average, a combustion engine can have more than 2,000 moving parts while an EV motor may have approximately 20 moving parts. EV’s are 85% more energy efficient (EV efficiency measured in miles per kilowatt-hour kWh) than ICE vehicles because of regenerative braking. As the EV is braking, or descending a hill, the kinetic energy is captured, converted in to electricity, then stored in the battery bank; an option not available in ICE vehicles. The lifetime efficiency of an EV is further enhanced by a lack of: oil changes, noise, vibrations, spark plugs, gear shifts (Clutch) and timing belts . . . Even reversing is efficient, for an EV to reverse, the motor simply spins backwards; in comparison, an ICE vehicle requires a transmission with complex gears that has to engage in order to move backwards.

The electric motor of an EV provides a constant stream of torque directly to the wheels without the need for a multi-speed transmission and complex gears. Some “EV motors” have the ability to generate 20,000 revolutions per minutes (RPM), comparatively; “ICE engines” generate 7,000 RPM’s. However, the transmissions in EV’s function differently than an ICE vehicle multi-speed transmissions. Also, an EV transmission has less moving parts than an ICE multi-speed transmission. “upon stepping on the accelerator, electricity is immediately sent from the battery to the electric motor. The spinning motor—shaft—spins the gear box; aka: one-speed gearbox (Volkswagon ID), single-speed gear reducer (Nissan Leaf), and single-speed fixed gear (Tesla Model 3)” subsequently rotating the wheels.

NOTE: Plug-in hybrid electric vehicles (PHEV) use a combination of an electric motor and a combustion engine, ie: (2024 Mazda CX-90).

The near instantaneous torque of an EV motor has a propensity to exacerbate the normal wear-and-tear of the tires. The rapid acceleration, along with the added weight of the battery bank, can contribute to the release of airborne particulates from the friction of the tires against the road. According to a report from the Imperial College, of London, globally EV tires generate 4,800 metric tons of tire waste annually.

Manufacturers, like Hankook, specializing in EV specific tires have produced EV tires designed with special characteristics to reduce low rolling resistance forces that impede movement, reduce noise and increase range performance and decrease particulate emissions. An innovative feature is EV tires are designed with 25% increased lateral rigidity compared to a standard ICE tire inorder to handle the weight of an EV during acceleration and high torque turns. Ironically, an EV motor is so quiet that it enhances outside noise not usually noticed by passengers in an ICE vehicle such as external tire tread noise or even the wind. Noise absorbing materials in the Hankook EV tires dampen the noise generated by the tire treads so it does not transmit acoustics or vibrations in to the vehicle cabin. These features are designed to increase the lifespan, ride comfort and performance of EV tires. The next evolution of EV’s will incorporate in-wheel motors, like the indiGO SmartWheels™, that are mounted directly on to each wheel hub providing direct kinetic power and enhanced precision driving.

The myth of car tires melting on hot asphalt roads during extreme heat conditions caused by climate change has been busted with the knowledge that most tires are manufactured through a vulcanized process which bonds the rubber molecules with sulphur to increase the melting point to approximately > 1000. However, it has been reported that sections of asphalt roads can buckle under extreme heat events. Also, mechanical problems in ICE vehicles increase as brake fluids absorbs moisture from the high humidity impacting brake performance. Expanding hot air in car tires can cause tire blowouts or negatively impact the structural integrity of the tires.

Electric vehicles are only as green as the energy sources they obtain their electricity from. But even the average EV powered by the dirtiest carbon based fuel grid system is still better for the environment than the most efficient ICE vehicles. Ofcourse, the ideal is to power an EV exclusively from clean renewable energy sources such as solar, wind turbines, hydroelectric . . . As American energy utilities continue the move towards renewable energy sources the grid will become cleaner.

Whether through altruism or to lower their manufacturing cost EV manufacturers, like Tesla Motors, are taking advantage of innovations in lithium-ion batteries to gravitate away from the conflict mineral Cobalt (Co) which makes up to 30% of a Lithium battery chemistry. The world’s largest producer of Cobalt, Democratic Republic of The Congo (DRC), accounts for 60% of global production; 100,000 MT's in 2019. Cobalt is easier & cheaper to extract in the DRC compared to Australia; the global #2 producer of Cobalt. Control of the Cobalt mines in the DRC are crucial to the funding of armed groups whom wage wars and dominate the population. The armed groups impose corruption, sexual exploitation, forced labor, child labor, unsafe working conditions and cause environmental pollution . . . Most of the DRC mines use modern mechanical equipment while atleast 20% rely on rudimentary hand tools and unsafe structural mining practices (Artisanal mines).

While ICE vehicles consume fossil fuels requiring the combustion of over 5,400 gallons of gasoline in its driving lifetime an EV only requires the initial mining of raw metals, once, during manufacturing; at the end-of-life of the battery the metals can then be repurposed or recycled. The efficiency of EV batteries extend their intended use in EV’s to be repurposed as battery storage in homes or deconstructed for their raw metals. By recycling the precious metals in retired batteries instead of sourcing virgin metals the EV battery manufacturers have lowered manufacturing cost while accomplishing unintended environmental benefits. Companies like Li-Cycle, in Gilbert, Arizona, has a “95% recycling efficiency rate to return valuable commodity materials found in used Lithium-ion batteries back to the supply chain.” Li-Cycle sustainable and work place safe methods use a proprietary hydrometallurgy process that does not require Oxygen; preventing any potential for a thermal event. A filter press is used to extract “Black Mass” containing Nickel (Ni), Cobalt (Co), Lithium (Li) . . .; including packaging materials such as plastics and vermiculate (Flame retardant). No smelting methods are used in the extraction process and water is used in a closed loop. Large, heavy, decommissioned EV batteries do not require manual dismantling and can be processed intact; increasing work place safety.

Besides transportation, an EV can serve another purpose though bidirectional EV to home charging. Some EV’s can be integrated with the existing home energy electrical system, along with the home solar, to provide daily or emergency home energy electricity. As EV battery prices lower and their capacity increases, it’s possible for an EV to have a larger battery capacity than a standard residential battery backup system; like a single residential Tesla Powerall.

It may seem counterintuitive that emission free vehicles are not a panacea to reducing transportation generated CO₂ emissions; considering that the global transportation sector contributes 20% of CO₂ emissions which contributes to climate change. Reducing the need for private transportation of people and goods in our society, regardless of their energy sources, should be the main focus of sustainable transportation. We have already seen the benefits of sustainable city designs that facilitate walking, the use of bicycles and —electrified— public transportation exhibited by a cleaner environment and a healthier more active population.

NOTE: The use of E-bikes (aka Pedelec), powered from renewable energy sources, generates lower CO₂ emissions than a human riding a nonelectric bicycle traveling the same distance and time due to the riders’ caloric metabolism of food; with the possible exception of Vegans and Vegetarians.

The U.S. public transportation system, in the form of buses & trains, prevents the release of 37 million metric tons of CO₂ annually; the equivalent of 11 million gallons of gasoline per day, 4.2 billion gallons of gasoline annually. Other benefits includes, but are not limited to, reduced vehicle congestion, reduced motor vehicle accidents and obviously cleaner air. Reducing the proximity of foods & services within walking or biking distance of residential consumers; along with an efficient electrified public rail and bus transportation system—That accommodates accessibility for all riders—will reduce the dependence on individual automobile ownership and the risk of sedentary diseases.

Please share your thoughts or experiences in the Comment section below.