OFF-GRID SOLAR ARRAY MOUNTING CLAMPS & METAL ROOFING

Photo courtesy of Roofing Magazine

The Tiny Off-Grid House roof design follows function with a 8/12 pitched 33.75° degree metal shed roof sloping at an angle that enables the maximum south facing sunrays to be perpendicular to the solar array even when the sun path is at its lowest arch during the winter months. Also the roof slope facilitates maximum rainwater and snow melt harvesting per square feet of roof space. The roof insulation will be constructed of 5/8” ZIP R System Sheathing which has a R-Value of 3.6 and will provide a strong base to anchor the metal roof; along with closed cell foam installation within the metal roof rafters. The metal roof panels are made of marine grade Aluminum (Al) panels, along with the cladding (Siding) vertical boards and batten panels are: corrosion resistant, Class A fire resistant, non-combustable, very lite weight, non porous, UV color stable, requires little if no maintenance, provides protection against insects (Termites), resistant to salt water corrosion, dissipates heat faster than wood and most of all Aluminum is 100% recyclable infinitely without loosing its quality each time. The metal cladding can cause some noise nuisance during heavy rains, graupels, or hail which can be mitigated with proper insulation under the metal cladding; along with a water barrier peel and stick underlayment which covers over the entire ZIP R system insulation from the gutter up to the eaves.

Photo courtesy of Indiamart

A 24 gauge (0.024”) steel roof is strong but not too heavy. As the gauge numbers increase 26, 28 . . . the metal becomes thinner and less rigid; subsequently, more susceptible to damage. A 24 gauge should provide a Class 4 impact rating (UL 2218 Standard for Impact Resistance of Prepared Roof Covering Materials). Hail damage can be separated in to two categories: cosmetic hail damage or structural hail damage; each prioritized according to the type of property/casualty insurance coverage policy & exclusions. Hail causing cosmetic dents or dimples may not compromise the structural integrity of the metal roof unless it results in perforation, cracking, of the paint or substrate which has the potential to cause structural failure.. In hail prone regions, an investment in non-flat striation metal panels, steeper roof slopes, supportive substrate and stronger panels can mitigate cosmetic and structural damages.

Aluminum cladding does not react to changes in the weather by warping or cracking. Aluminum cladding is a poor thermal conductor and when not exposed to a continued heat source it dissipates heat quickly—because it is less dense; compared to wood and especially concrete. When aluminum is exposed to cold it increases the strength of the metal and it does not become brittle.

The aluminum panels are made by an extrusion process (press and die). Then electrostatic guns are used to deliver a VOC free, lead free, powder coated color that is scratch resistant and UV color stable. The last step is Polymerization where the panels will be heated >200° celsius. Electrolytic Anodizing provides a protective oxide layer against corrosion and strengthens the metal along with facilitating paint adhering to the metal surface. The last step is Polymerization where the panels will be heated >200° Celsius. Electrolytic Anodizing provides a protective oxide layer against corrosion and strengthens the metal along with facilitating paint adhering to the metal surface. The aluminum wall panels are arranged in a board and batten vertical siding.

Photo courtesy of Pinterest

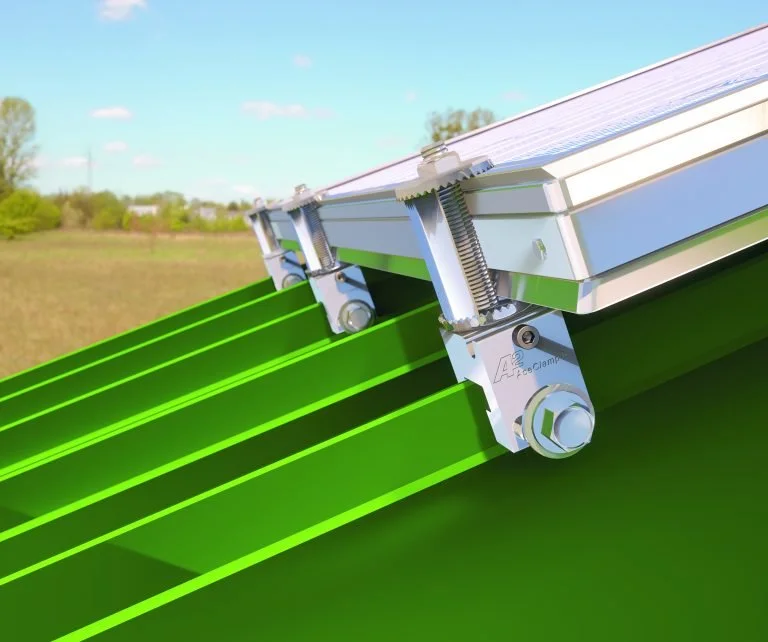

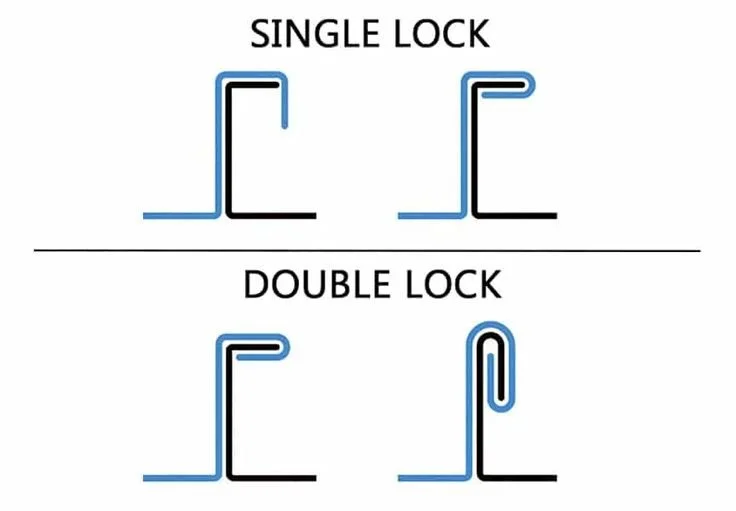

Standing Seam metal roofs come in three profiles Snaplock, mechanical & flange: Snaplock does no require a hand or mechanical seamer. Fastener clips attach to the male seam securing the panel to the roof. Male and female seams simply snap on together. More fastener clips, than usually needed for installation, is required to better secure a solar array. The solar array is not secured to the roof but clipped on to the roof panels.

Mechanical lock seams requires a hand or mechanical seamer to bend and fold the female and male edges to create either a single 90° or more preferable double lock 180° seam (low slop). A mechanical sliding/expansion clip is attached to the male seam which secures the panel to the roof but allows expansion/contraction movements. These movements can be caused by thermal expansion due to the heat from the sun or contraction in cold weather. Mechanical double lock 1 1/2 seamed ribs provide a secure anchor for the roof top solar solar modules mounting clamps without the added weight of rails.

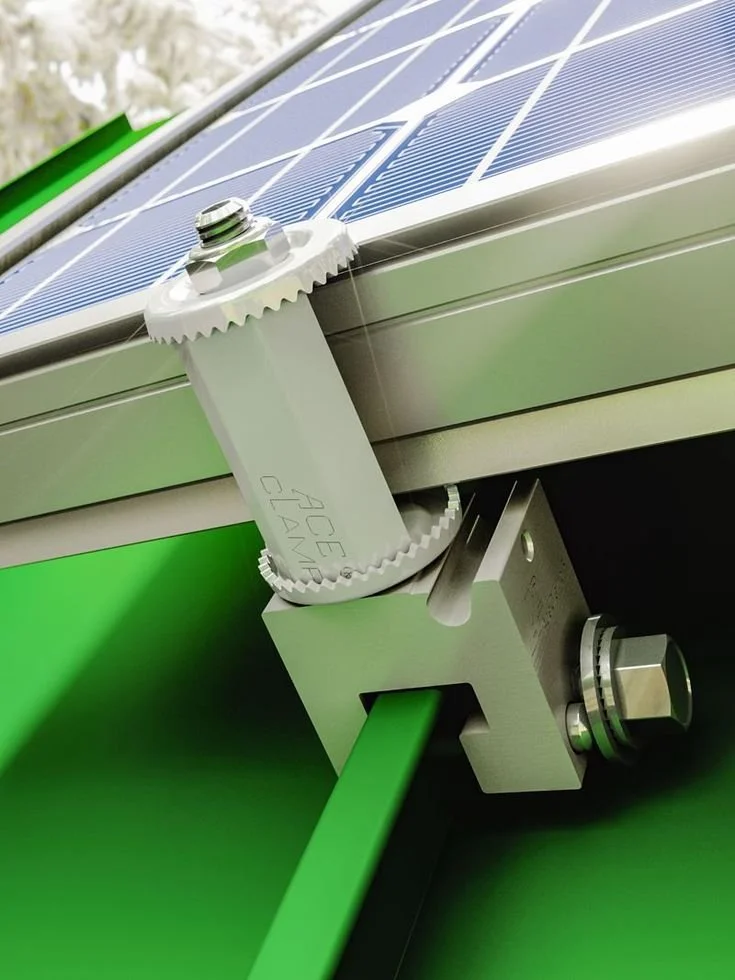

Photo courtesy of AceClamps

SOLAR MODULE MOUNTING CLAMPS:

Th solar array will be attached to the metal roof with a “railless” system using non-penetrating AceClamp A2® metal roof clamps that secures each solar module on to the vertical double lock seams of the metal roof; avoiding penetrations in to the metal that may compromise the air/water tight envelope of the roof.

For more information on wiring & sizing a solar array please read “Off Grid Solar”

Instead of using traditional set screws, AceClamps use a sliding pin clamp that secures to the roof seam that prevents potential damage to the “panel coating finish from rotational forces and sharp edge that have been shown to be the cause of certain types of damage that can become a nightmare to contractors, such as pierced panels and rust staining.” This preventable damage may void the warranty of the metal roof.

Since the solar modules will be secured directly on to the metal panels and not floating on rails, the modules will be attached to the standing seams securely with sufficient amounts of attachment clamps the can withstand the weight of ice and snow and any aerodynamic lift forces created from the solar array.

The solar panels mounting clamps should be tightened with a torque device to ensure manufacturers specs for tightening are properly achieved.

Photo courtesy of AceClamps

Fastener/nail flange use nails to penetrate the male side of the panel to secure it to the roof; then the female side snaps over the male side hiding the nail penetrations. In an air-tight envelope, the less nails, the less chance of air and water penetrations.

There are two types of metal roof installations: exposed fasteners with EPDM gaskets and standing seam. The gaskets, on exposed zinc coated fasteners, are vulnerable to longterm exposure to UV rays. While little to no screws or rivets are visible on a standing seam metal roof. This method is preferred to avoid exposed roof penetrations and maintain the air/water tight integrity of the metal roof.

Metal roofs are no more susceptible to lightening strikes than any other types of roofs. Still, precautions are taken by the installation of a lightening rod, grounding rod and lightening arresters since the structure location on an open field may make it more susceptible to opportunistic lightening strikes.

For more information on house lightening protection please read “Tiny Off-Grid House Lightning Protection”

Oil canning is a cosmetic nuisance in the appearance of metal roofs reacting to changes in the weather, the manufacturing process or after installation on a flat roof without support ribs. Flat metal panels are more susceptible to oil canning. Metal panels with striations help mitigate the formations of oil canning.

The need for installing a radiant barrier is possibly negated by the installation of a solar array. According to Eenrgysage, “installing solar panels will block this sunlight from hitting your roof, thereby preventing heat from entering your house. The researchers found that solar panels can lower a roof’s temperature by 5 degrees Fahrenheit, or about 3 degrees Celsius.” So besides primarily producing electricity, the unintended cooling benefits of the solar array shading the Tiny Off-Grid House roof will result in reduced electricity needed to cool the Tiny Off-grid House during the hot, humid, summers.

A light color roof will reflect more sunlight than a darker color roof. A white color roof will keep the roof cooler, reducing the heat stress on the Tiny Off-Grid House and the energy needed for cooling the interior. The same contaminant and VOCs requirements for the interior paints is required for the exterior paint; especially, not to compromise the quality of the water catchment rainwater or snowmelt.

Wherever possible, roof penetrations and especially square penetrations, should be avoided or mitigated with sealants or weatherproofing. The main solar array home run for the electrical wires enter at the lowest point (Starboard) of the roof through a pipe boot in to the engineering compartment. The pipe boot is usually made of UV resistant Ethylene Propylene Diene Monomer (EPDM) rubber. EPDM long term environmental impact is significantly lower than other commercial roofing products. A steel ring around the pipe boot flange secures the rubber to the flat surface of a metal panel to allow for movement while the top can be cut to the specific conduit diameter then secured with a collar band. Pipe boots are manufactured in a variety of colors to match the roof color.

RAIN WATER HARVESTING:

Rain water harvesting should only be preformed on metal roofs that will not contaminate the water with debris, rust, paint, oils . . . Unlike Copper, an Aluminum metal roof should not leach metal in to the water through a process called diffusion. Leached Zinc from galvanized roofs are harmful not only to humans but to vegetation since it is a herbicide. Research is ongoing on the effects of Zinc leaching from galvalome, not to be confused with galvanized roofs? Water catchment on a metal roof and solar panels are better than roofs made of other materials that may contaminate the rainwater. Harvesting rainwater from roofing material made of lead, copper, tin, galvanized (Zinc) or wood (usually treated with fire retardants), antimicrobial paints (Zinc & Copper used to combat fecal materials and moss growth) should be avoided. Also, debris are less prone to adhere to the metal. However, rain water harvesting should only be preformed on metal roofs that would not infuse the water with metals. Unlike Copper, an Aluminum metal roof is less prone to leach metal in to the water through a process called osmosis.

For more information on harvesting rainwater please read “Rain Water Catchment & Filtration”

SUSTAINABILITY:

The metal roof and cladding, along with rainwater and snowmelt conduits are all recyclable and may have inherently been manufactured from other recycled metals. Household construction and demolition waste are a significant portion of landfill waste. The sustainable design of the Tiny Off-Grid House minimizes the production of construction waste by using sustainable building products and precision engineering methods to reduce the production of construction waste.

Please share your thoughts or experiences in the Comments section below.