HEAT-PUMP AIR CONDITIONING & HEATING FOR A TINY HOUSE

Image courtesy of Mitsubishi

According to year 2020 data, 52% of U.S. residential annual energy consumption is exclusively for space heating and air conditioning. An additional 25% of energy is consumed by: refrigeration, water heating and lighting; with the remaining 23% consumed by appliances.

The Tiny Off-Grid House, off-grid powered, heating & cooling of the indoor ambient temperature, air filtration and dehumidification is primarily accomplished through an ENERGY STAR, air-sourced, ductless, wall mounted, programmable thermostat, Heat Pump, commonly referred to as a Mini Split or in Europe, as a Reverse Cycle Air Conditioner. Indoor comfort temperatures are maintained by closed cell foam thermal / vapor insulation, with the aide of Lunos heat recovery ventilator (HRV) system and a programmable thermostat. The triad system is inextricable needed for maintaining the conditioned temperature and the mechanical integrity of the structure. It’s very simple, the more efficiently a house retains heat, the less heating expenditure that is needed.

To achieve a maximum air tight, moisture resistant, closed building envelope “closed cell” spray foam (spray polyurethane, SPF) nonpermeable insulation and the Huberwood ZIP System® will be used as a whole house insulation and vapor barrier in the Tiny Off-Grid House. For more information, please read “Tiny Off-Grid House Insulation & Vapor Barrier”

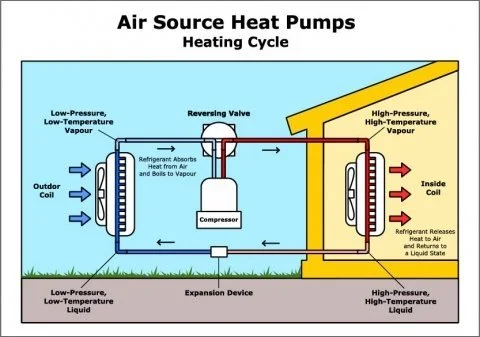

A Mini Split does not generate its own heat; its main function is the “relocation” of latent heat energy. A refrigerant is circulated in Aluminum or Copper coils to either release or absorb heat from the ambient air outside to heat or cool the house through a compression or expansion cycle that is powered by electricity. It accomplishes this task with extreme efficiency with the highest coefficiency of performance (CoP) to turn electricity in to heat energy.

ENERGY EFFICIENCY RATING

When compared to a conventional thermal heating unit, a Mini-Split has a CoP of 2.5 or greater, using 1/5 the energy required for a thermal electric heater that is running at 95% efficiency. Most of the Mini Split electrical consumption is from the Compressor. Carbon fueled heaters will not be included in this research: Propane heaters with their harmful fumes and moisture emissions; nor, wood stoves emitting particulate matter and dry heat with both having less efficiency of CoP compared to a Mini-Split.

Mini Split are 3X’s more efficient than oil-fueled systems. The efficiency rating of air conditioners are established by the Air Conditioning Heating Refrigeration Institute (AHRI) in the form of Seasonal Energy Efficiency Rating (SEER 2) for cooling efficiency and Heating Seasonal Performance Factor (HSPF) for heating efficiency. The higher the number rating of SEER 2 and HSPF the greater the equipment energy efficiency. SEER 2 (For equipment manufactured after 1/1/2023) has a minimum efficiency rating of 14 and a high of 16.

HSPF measures the efficiency of air sourced mini splits (BTU / Watts-Hrs). A minimum rating for ENERGY STAR certified mini splits is 8.5; with some modern models rating up to 14 HSPF.

An Annual Fuel Utilization Efficiency (AFUE) rating also measures heating efficiently, but of carbon fuel combustion in to heat energy; in a furnace. Subsequently, the AFUE rating is mute for electric powered mini splits.

The Mini Split performance for a desired space depends on the amount of British Thermal Units (BTU’s) it is capable of producing. The BTU is a unit of measurement that is used to determine how much heat to remove or to provide to condition the space. The BTU is determined by the dimensions of the space (L x W x H), number of doors and windows, along with the type of insulation and number of occupants in the space.

CONS

Cost - The perceived high cost of electric appliances are off-set by a fast return on investment through lower (Free off-grid) energy cost and incentives through Federal tax credits, state & utility rebates which makes upgrading to electric appliances attainable

Extreme cold weather inefficiency - See “Winter Operation” below

Maintenance - The Evaporator HEPA filter and coils require seasonal cleaning / maintenance

PROS

EnergyStar - Energy efficient operation

Dual heating & cooling

Cleaner operation - Does not generate fumes or particulate matter from carbon fuel combustion

Energy efficiency

Point of use heating & cooling - Air is difficult to move. Since the air is heated or cooled at its destination of use, less energy is required to move the conditioned air

Ductless - Ducts losses, through leaks, account for more than 40% energy consumption.

Safety - No carbon emissions. Power provided by electrical energy; with no fear of oil or gas leaks

Windowless installation - The Evaporator and Condenser can be installed in proximity of each other where desired with no constraints of needing access to a window like a conventional window mounted air conditioner

Low noise operation - A Mini-Split operates remarkably quiet considering it’s intended purpose. Noises, from vibrations, are reduced by regular maintenance and the use of anti-vibration gaskets on the wall mounting brackets. The operating decibels should not violate any reasonable regulatory noise ordinances

Dehumidifier - See Summer Operation below

HEPA Filtration - Filter small particulate matter & bacteria entering the indoor air space

Comfort heat - The qualitative heat generated does not feel like dry hot air often associated with gas furnaces

A Mini-Split has two main components: an indoor Evaporator (aka Air Handler, The head) and an outside Condenser (Compressor). The condenser requires one small penetration through the air tight envelope for passage of the power conductors to the main service panel while the evaporator requires a 3” penetration for the refrigerant line, drain line and power/communication conductors. A 238 Sq Ft. living space should probably be satisfied by a 1 ton, 6 - 8,000 BTU Mini-Spilt, with variable speed air compressor, for cold climates.

A refrigerant is used to either release or absorb latent heat energy with the aide of an air compressor; which creates a pressure gradient to condense the refrigerant, releasing latent heat of vaporization; or an expansion valve to regulate the volume of refrigerant to absorb latent heat energy. A reversing valve changes the direction of the refrigerant in the coils for cooling or heat mode.

SUMMER OPERATION

The low pressure, low temperature, liquid refrigerant absorbs ambient heat by the evaporator fan blowing hot indoor air over the refrigerant filled heat exchange coils; subsequently, cooling the space. The high pressure evaporates the refrigerant in to a gas absorbing heat from the warm indoor space. The Condenser fan blows outside ambient air over the high pressure, high temperature, refrigerant filled heat exchanger coils, condensing the refrigerant back to a liquid.

The cool surface of the Evaporator coils causes the water content in the humid indoor air to condense water in to the collection tray which empties out the drain hose outside. As a bonus, the cool air that comes out the Evaporator is dehumidified, recirculated and cleaned by a HEPA filter. (See image below)

Image courtesy of Energy.Gov

WINTER OPERATION

Even if the outside temperature is cold, there is still latent heat that can be extracted from the cold air. Modern Mini Splits can operate in temperatures as cold as -25 C. Some models are designed specifically for greater efficiency during cold temperatures. The Mitsubishi Hyper Heat (MXZ-3C30NAHZ) and the LG RED models are designed to maintain 90% efficiency in 13° F (1.9° C) weather.

In cold temperatures, the Condenser Reversing Valve reverses the flow of refrigerant, from cooling phase, to absorb heat from the outside air. High pressure, high temperature, liquid refrigerant goes through an Expansion Valve which decreases the pressure and temperature of the liquid refrigerant in the Condenser coils. The low pressure, low temperature liquid refrigerant enters the condenser where it absorbs heat energy from the outside air; causing the refrigerant to boil and turn in to vapor.

A Compresser then pumps the now high pressure, high temperature, vapor in to the indoor Evaporator. The heat in the refrigerant naturally gravitates to the cold indoor space. As the refrigerant releases heat in to the air it returns to a liquid phase.

A Mini-Split operating above 40 °F may have a 100% efficiency rate. However, as temperatures lower the unit will still generate heat but with less efficiency; requiring more power consumption. This is due to the low ambient heat available outside for it to operate with higher efficiency. Also, the performance of a Mini-Split can be impacted by below freezing temperatures below the dew point of the air that causes moisture to freeze on the condenser coils; impeding air flow, requiring defrosting. Defrosting is accomplished rather quickly by reversing the phase to Summer Operation temporarily exhausting heat from the heated space to defrost the outside condenser coils.

Image courtesy of Mitsubishi

REFRIGERANT

A replacement refrigerant to R-22 (A Chlorofuorocarbon (CFCs) trade name Freon; (outlawed in 2010 for new AC units), often referred to as R-410A1; trade name Puron. R-410A1 increases the efficiency of the condenser to operate longer and at higher pressures than inefficient Freon. Puron is a hydro-fluorocarbon (HFC) that does not contribute to ozone depletion like R-22. However, it is a greenhouse gas that contributes to climate change. The consolation is that it is short lived in the atmosphere. The Kigali amendment to the Montreal Protocol, on October 15, 2016, included the phasing out of HFCs by 2047, at a minimum, to be replaced with safer alternatives that has an ozone depletion potential (ODP) = O, along with a low global warming potential (GWP). For reference, Methane gas has a GWP of 34 and CO₂ GWP = 1.

SMART OPERATION

Energy efficiency increases when Smart technology is used in Mini-Splits allowing remote and automatic operation. The comfort temperature can be set to activate prior to the arrival of the occupant(s).

Some Mini-Split models allows the Evaporator vent to focus air flow on specific sections of the room —Zone— that is exhibiting occupancy / activity. This further increases energy efficiency by focusing heating or cooling air directly on to the occupant(s). According to Neil deGrasse Tyson, Astrophysicist, “air above the skin removes heat from the body.” The human skin (97° F / 36° C) releases heat to the Real Feel Temperature (aka Wind Chill Factor) of the colder air blowing against the skin. In nature, during the summer, this action is called a “cool breeze.”

INSTALLATION

The modest energy consumption requires 120 Volts, AC, through a 30 Amps double-pole circuit breaker wired to 6/4 AWG copper conductors. Wiring is made even more easier since the outside condenser feeds power to the inside evaporator. An outdoor electrical disconnect is required within sight and readily accessible near the condenser (2023 NEC 440.14).

The exterior refrigerant lines must be insulated and a line cover kit—if possible, matching the color of the metal wall sheathing—should be installed covering the refrigerant lines, with a minimum R8 insulation, to protectthem from UV damage, blunt force damage and weathering, along with providing aesthetics.

The metal wall studs will have to be reinforced or increased in number in the areas the Evaporator is to be installed to make sure it is anchored to the wall frame properly. While the base of the Condenser will be secured on to the trailer tongue; high enough, above the ground, to avoid snow accumulation.

MAINTENANCE

Clean, or if necessary, replace Evaporator filter; every 4 - 6 weeks

Clean Condenser coils; every; 4 - 6 weeks

Check, if necessary clear, drain hose and repair any kinks in the hose

Keep Condenser ground area clear of debris, foliage or snow; at all times

FINANCIAL INCENTIVES *

Financial incentives in the forms of U.S. federal tax credits (IRS Form 5695 Residential Energy Credits), through the Congressional Bipartisan Inflation Reduction Act signed in to law by President Joe Biden on August 16, 2022 gives eligible customers a tax credit of 30% of the cost, up to $2,000., for the purchase of a single or a multi zone Mini Split (Valid 01/01/2023 - 12/31/2034). Plus, up to $600. for electrical upgrades to accommodate installation of a Mini Split. Inaddition, States and local power utilies also provide rebates. However, only select energy efficient models may qualify.

* The information provided does not constitute professional tax advice or professional financial guidance. Please consult a tax professional.

Please share your thoughts or experiences in the Comments section below.