TINY OFF-GRID HOUSE TRAILER DESIGN & INSULATION

Image courtesy of Mint Tiny Homes

A trailer on wheels with a tiny house bolted on top is literally the foundation of the Tiny House movement. Advances in Tiny House trailer designs have improved strength and reduced weight. However, the one area of needed improvement is insulation of the trailer subfloor.

Tiny House trailer design is governed by U.S. Department of Transportation (DoT) “road rules." Any deviation from these federal highway regulations may require an upgraded drivers license and/or a special road permit for transportation and restriction from Parkways—which usually have low bridges or narrow roadways compared to Expressways.

These DoT minimum road regulations impacts the weight, width and height design of the Tiny Off-Grid House. Exceeding the maximum height of 13’.5” and max width of 8’ 5” (102”) may restrict road access under bridges, trestles or through highway toll stations. The width of the Tiny Off-Grid House trailer frame will be between 92” to 102” to account for the ZIP-R insulated wall panels and metal sheathing. The average maximum trailer length in most states is 53’; which includes the tow vehicle. The Tiny Off-Grid House total length will be 28’. The weight and length of a trailer may determine the type of drivers license and special road permit(s) required for towing. The weight will also influence trailer construction by determining the number of wheel axles needed to transport and stabilize the total weight of the structure. On average, the maximum trailer weight is 73,000 lbs.

STANDARD TRAILER PARTS

The names of most trailer parts are functionally descriptive (Further details or notes are elaborated in brackets)

The nontorsionally rigid frame is made of high - strength steel

Belly Pan fully welded to bottom of frame and Cross Members. No vent or drainage access required on Belly Pan (Keep out road debris, vermin, insects and moisture from entering deck)

Anticorrosion protection black paint coating (Reapplied where ever penetrations are made in to the trailer)

Triple Axles (7,000 lbs each, 21,000 GVW)

235/80R 16” Rims, 10 ply radial tires

Structural “square” wheel fenders

Exterior frame (2 x 6 square-tube steel structural frame)

2 x 4 square-tube steel Cross Members, spaced 16” center-to-center (Replaces the need for a wooden subfloor in the deck)

Deck (Center cavity of the trailer frame)

Tongue Jack stand with spring retraction raises/lowers the front ball hitch. A “front” facing hand crank for clearance of an optional bump-out or Mini-Split condenser

Wiring Harness (7-pin plug that powers running lights, turn signals and electric brakes

Electric brakes

Running and Brake, DoT approved, LED lights

Side markers, Dot approved, LED lights

Trailer Tongue

Standard 2 - 5/16” Ball Coupler Hitch with locking mechanism

Heavy duty safety chain (Attaches to transport vehicle hitch assembly)

D-Rings Tie down attachments (Anchor points for tie downs straps against high winds)

U.S. DoT & VIN stickers

Emergency breakaway kit with safety chain & battery (When detached, activates electric brakes)

Pre-welded corner Scissor Leveling Jacks (Positioned on the four corners of trailer to level trailer when parked will not be installed. If the ground is not level, the welded jacks can extend at an uneven angle forcing the trailer to tilt to one side. If necessary, the Tiny Off-Grid House will use non-welded Jack Stands will be used)

Pre-welded 1/2” threaded vertical rods are used to secure the walls to the trailer.

NEW VS USED TRAILER

In order to not compromise the research of the Tiny Off-Grid House, a new trailer will be used —no pun intended— since it will be difficult to verify the integrity of the building materials and paint toxicity from a used trailer .

TYPES OF TRAILERS

There are three categories of trailers suitable for Tiny Houses: deck over, gooseneck (5th Wheel) and bumper-pull. The various styles of trailers have practical origins based on their functions in industry. Some trailer types not recommended are dove tails. The rear ramp slopes the floor down creating an uneven foundation.

The deck over provides a full width subfloor without any wheel fenders protruding in to the living space floor; but sacrifices potential headroom below and above the lofts; if any. Also, the deck over maybe prone to leaning to one side.

The Gooseneck trailer offers the most road stability during transport; however, it has to be hauled using a pickup truck with a King Pin Lock. Another benefit the gooseneck offers is standing height loft space above the King Pin Lock.

The ideal trailer for the Tiny Off-Grid House would be a bumper-pull trailer with a full width subfloor; incorporating the wheel fenders, but not exceeding 8’ 5” W. Room would be reserved for the exterior wall sidings to complete the full 8” 5” width. A trailer with a full width subfloor is preferred to eliminate non insulated corners. Trailers with uninsulated perimeter flanges or outriggers are susceptible to thermal bridging between the corners where the perimeter walls and subfloor meet with the potential to form condensation near the inside corners of the Tiny House floor.

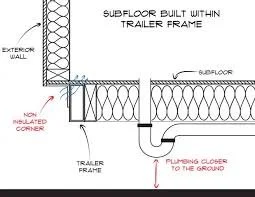

Image courtesy of Tiny Home Builders

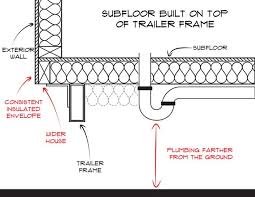

Image courtesy of Tiny Home Builders

TRAILER SUBFLOOR INSULATION

Some Tiny House trailer models have a perimeter flange where the exterior walls are anchored and supported. However, a perimeter flange has the potential to facilitate thermal bridging since an uninsulated corner is formed where the subfloor and exterior walls meet. This vulnerability causes condensation to form inside the living space. In order to maintain a consistent insulated envelope the Tiny Off-Grid House will require a trailer with a full width subfloor, built within the trailer frame, that extends out to the space usually occupied by the vulnerable perimeter flange; eliminating any uninsulated corners. The full width subfloor will be insulated with “closed” spray polyurethane foam (SPF) insulation on top of a welded belly pan. The belly pan welded, not riveted, to the bottom of the main frame and cross members will keep out moisture, vermin, insects and road debris.

Over compensating by building the insulated subfloor elevated over the trailer decking and flange definitely eliminates any non insulated corners but takes away valuable headroom from inside the living space.

Closed cell foam will insulate the cavity of the decking which includes the metal running beam and cross members. Closed cell foam is filled with insulating cells, filled with gas, fully encapsulated by its cell-wall and not interconnecting with other cells creating its own vapor barrier that prevents air and moisture to penetrate inside the foam. Spray foam immediately expands and adheres to the wall surfaces it is applied to without the need for glues or adhesive tape; even to the undersides of a roof. Cell foam insulation has the ability to expand in between the runner beams and cross members when applied in to the cavity of the trailer deck. At a 1” thickness when fully expanded, closed cell foam has a high R-value of R 6.0 per one inch.; R 13.0 per two inches, R 19.0 per three inches (Long Term Thermal Resistance Values of Walltite) . .

For more information on insulation & vapor barrier, please read: “Tiny Off-Grid House Insulation & Vapor Barrier”.

The closed cell foam insulation will eventually be topped with AdvanTech® subfloors. According to Advan Tech®, their subfloors are rigid and squeak free; providing a moisture resistant barrier.

The majority of grey water drainage pipe within the insulated trailer frame will be protected from freezing in cold temperatures and debris damage from the road.

Skirting, in and of itself, the bottom perimeter of the trailer is not a solution to stop cold air from lowering the temperature under a trailer. Bales of hay or planks of wood have been used to block cold convective air flow flowing under the trailer. Some have even compared the convective nature of cold air flowing under a trailer as similar to cold air flowing under a bridge and icing the roadway. Only with the installation of adequate insulation in the trailer subfloor can skirting provide some form of secondary assistance with insulation. Primarily, skirting may serve as an aesthetic benefit.

STRUCTURAL WHEEL FENDERS

The ninety degree corners of a square structural wheel is more practical than a curved fender which increase construction labor during installation of the walls. Since there is a likely potential to build a supporting structure above the wheel fender a “header” is required to be installed above the wheel fenders.

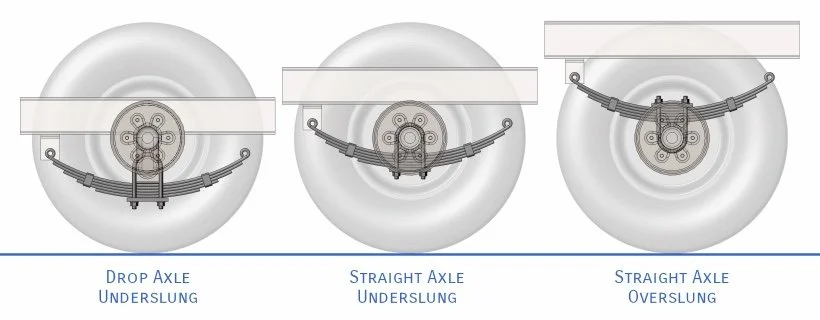

Image courtesy of Mechanical Elements

TRAILER AXLES

A trailer designed for a Tiny House has different axle requirements compared to car trailers. A Tiny House trailer must consider weight constraints and balance. Triple axles will be strategically positioned under the length of the trailer to provide proper weight distribution; 60% of the load in front of the axles and 40% behind. Each axle should have a minimum 7,000 lbs load rating. Three axles rated 7,000 lbs each equal a Gross Vehicle Weight Rating (GVWR) of 21,000 lbs. The GVWR max weight is the total weight the axles can carry (The total weight includes: the Tiny House trailer, occupants, furniture, appliances, full water tank and battery bank). A CAT truck scale can be used to determine the weight of the trailer and Tiny House.

NOTE: The Tiny Off-Grid House GVWR includes a full 55 gallon clean water tank weighing 458.7 lbs / 208.06 kg at 17 °C / 62 °F.

Trailer axles are rated according to their weight carrying capacity. In the United States there is no federal regulations for Tiny Houses on wheel weights; weight limits maybe regulated by local cities and towns. In the European Union (EU) maximum weight limits are 3.5 tons (7700 lbs), Australia 4.5 tons (7716 lbs) and in New Zealand 3500 kg (7716 lbs).

The Tiny Off-Grid House will utilize triple straight axles. Straight axle deck height is 26” above the ground while the wheel fender can be 9” to 10” above the deck.

DROP AXLES

A special discussion has to be made concerning drop axles. Drop axles can carry the same weight as a straight axle with the deck 21” to 22” above the ground while the wheel fender is 13” to 14” above the deck. Subsequently, the drop axle creates a 4” to 5” gain in head room space in the loft.

The lower clearance can be a hazard for longer trailers attempting to traverse steep slopes or uneven roads. Also, the lower clearance can be a concern for plumbing pipes and tanks projecting from the bottom of the trailer. Another concern, occurring during extreme weather events, is the low deck clearance during floods.

Con’s of Drop Axles:

Drop axles have lower ground clearance

The lower ground clearance limits steep slopes & off-road capabilities

The lower ground clearance compromises grey / black water plumbing pipes and tanks

The lower ground clearance limits the length of the trailer. A longer trailer increases the above mentioned concerns

Pro’s of Drop Axles:

Headroom in the loft space is increased

Stability is increased since the trailer center of gravity is lower relative to the wheels

ELECTRICAL GROUNDING OF TRAILER FRAME

The metal trailer can be a conductor of electricity from lightning strikes, electrical surges or as a return current to the battery negative terminal. Subsequently, a ground electrical conductor (GEC), #4 rated American Wire Gauge (AWG), stranded, low-impedance copper conductor, protected in green nonconductive sheathing, will bond the trailer to the electrical service grounding system bonded to a 8’ L ground rod embedded in the ground (Earth). The GEC will be bonded connected a bonding lug then bonded to the trailer frame with a serrated washer penetrating in to the trailer frame (IEC Graphical Symbol 60417-5020).

NOTE A small section of the trailer frame that has the anti-rust paint must be scrapped off to allow direct contact between the lug, serrated washer and the trailer frame.

After installation of the GEC to the trailer frame, anti-rust paint should be reapplied over the lug and exposed trailer frame section to prevent rust.

For more information please read “Tiny Off-Grid House Protection From Lightning Strikes And Electrical Surges.”

TINY OFF-GRID HOUSE TRAILER DESIGN BENEFITS

A full width subfloor is used instead of perimeter flanges

The full width subfloor is insulated with closed cell foam insulation & moisture barrier

Sufficient interior head room in the living space

Heavy duty straight triple underslung axles ensures balance and adequate weight management

Please share your thoughts or experiences in the Comments section below.